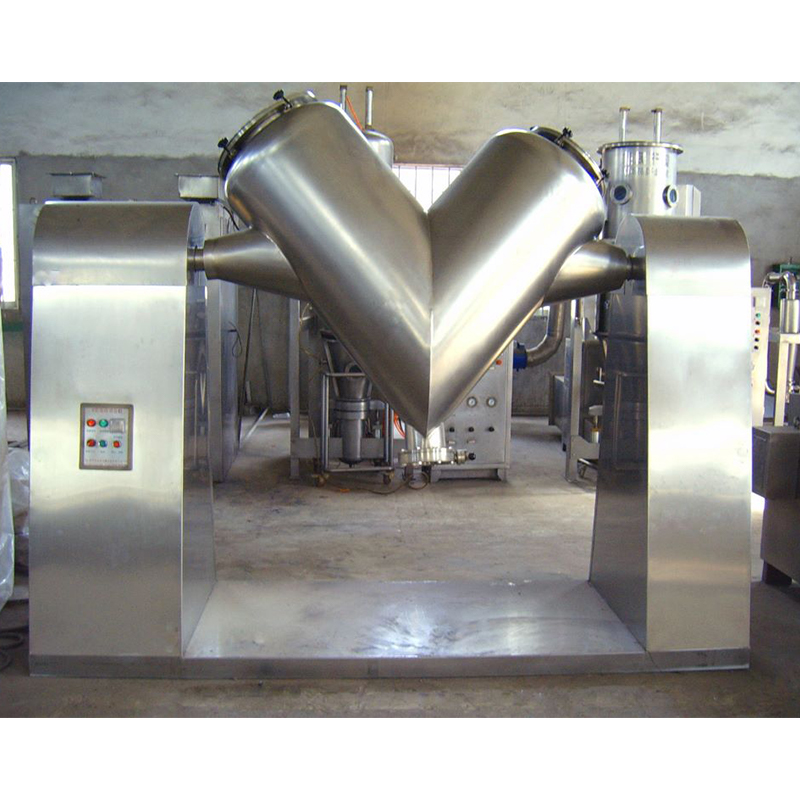

Application of Power (Granules) Mixer in various industries

1. Pharmaceutical industry: core equipment to ensure drug quality

In the pharmaceutical industry, the quality of drugs is directly related to the health of patients, so every link of drug production needs to be strictly controlled. The uniform mixing of granular drug raw materials, especially in the production of tablets, capsules and granules, requires extremely high mixing accuracy and consistency.

Power (Granules) Mixer can provide efficient mixing capabilities to ensure that the active ingredients and excipients of the drug are evenly distributed in each particle, avoiding the risk of unstable drug efficacy or inconsistent dosage due to uneven mixing. Modern Power (Granules) Mixer is usually equipped with an automated control system that can accurately control the mixing time, speed and temperature to maximize product quality.

For example, when producing antibiotics and vitamins, the active ingredients of the drug need to be mixed evenly with other excipients. Power (Granules) Mixer can effectively eliminate the differences between raw materials through its high-speed stirring function to ensure the stability and consistency of the final product.

2. Chemical industry: Improve raw material mixing uniformity and production efficiency

In the chemical industry, the production of many products requires precise proportioning and uniform mixing of different chemical substances. Traditional mixing methods often fail to meet the requirements, but Power (Granules) Mixer solves this problem with its high-speed and powerful mixing performance.

For example, in plastic production, plastic particles need to be mixed with different additives (such as colorants, plasticizers, fillers, etc.) to ensure that the composition and color of each plastic particle are consistent. Power (Granules) Mixer can ensure that various materials are evenly mixed in a short time through an optimized mixing device, and can adapt to materials with different viscosities and fluidities, reducing production cycles and energy consumption.

In addition, fertilizer production is also an important application area for Power (Granules) Mixer. During the production process, the main components of fertilizers need to be accurately mixed with trace elements, additives and other substances. Due to the wide variety of fertilizer particles and their strong viscosity, the efficient mixing performance of Power (Granules) Mixer can ensure the uniformity of each fertilizer particle, thereby improving the nutrient absorption effect of crops.

3. Food industry: improving food quality and taste

In the food industry, especially in the mixing process of granular materials such as flour, sugar, and salt, Power (Granules) Mixer plays an irreplaceable role. In food production, the uniform mixing of powder, granules and liquid raw materials is an important process to ensure the taste, quality and nutrition of food.

For example, when producing candies, biscuits, instant drinks and other foods, the ratio and mixing quality of the raw materials directly affect the taste and appearance of the final product. Power (Granules) Mixer can quickly and evenly mix raw materials of different properties to ensure that each batch of food produced has a consistent taste and meets quality standards.

In addition, the food industry has extremely high requirements for hygiene. Power (Granules) Mixer is usually made of stainless steel and has an easy-to-clean design to ensure that it will not be contaminated during the production process and comply with food safety regulations.

4. Agricultural industry: improving crop yield and quality

In the agricultural field, Power (Granules) Mixer is widely used in the production and granulation of fertilizers and pesticides. The uniform mixing of fertilizer granules and the precise preparation of pesticide formulas directly affect the growth and yield of crops.

For example, in the production process of compound fertilizer, basic elements such as nitrogen, phosphorus, and potassium need to be evenly mixed with trace elements. Power (Granules) Mixer can ensure the uniformity of fertilizer particles, thereby effectively improving the growth quality and nutrient absorption rate of crops. For the production of pesticides, the uniformity of mixing also determines the efficacy and safety of application. Power (Granules) Mixer can ensure the uniform distribution of pesticide ingredients and improve the application effect.

In addition, the agricultural industry has high requirements for the stability and durability of equipment. Power (Granules) Mixer usually uses corrosion-resistant and wear-resistant materials to ensure that the equipment can operate stably for a long time when handling complex materials.

5. Plastics industry: ensuring the consistency of plastic products

In the production process of the plastics industry, a large amount of granular materials and chemical additives are mixed. Power (Granules) Mixer is widely used in the mixing of plastic particles. Through the high-efficiency stirring device, it ensures that raw materials of different particle sizes and characteristics are evenly mixed, thereby improving the strength, toughness and appearance quality of the final product.

For example, when producing plastic pipes, the mixing process requires that plastic particles, plasticizers, stabilizers, colorants and other additives must be evenly distributed, otherwise it may lead to poor mechanical properties of the pipe or even uneven color. The Power (Granules) Mixer can complete this process in a short time to ensure stable product quality.

English

English русский

русский عربى

عربى Türk

Türk